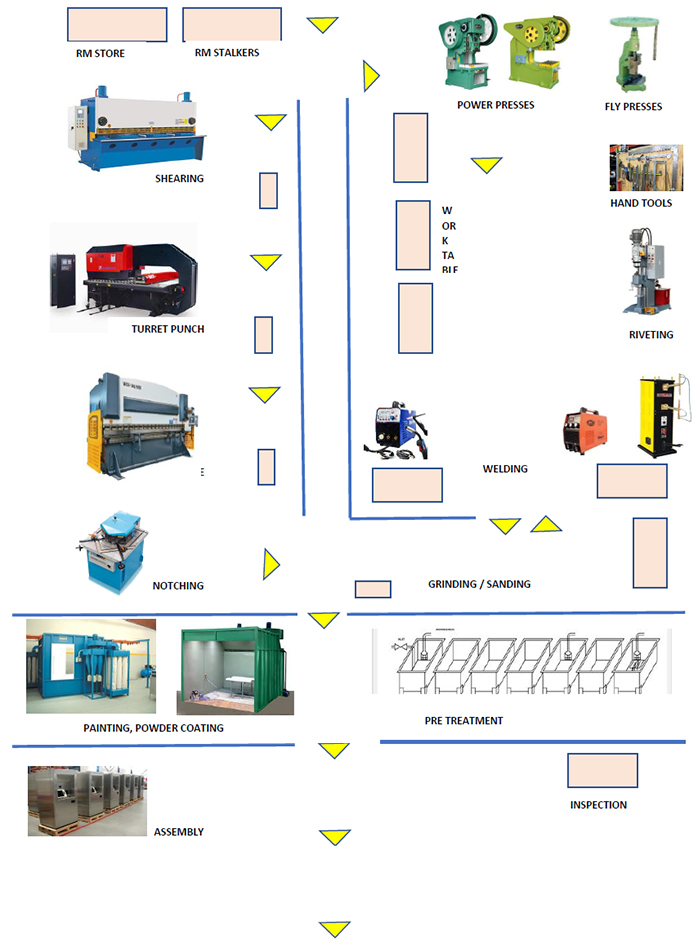

As discussed earlier the equipment of a sheet metal shop varies widely depending upon the size of the product and production quantities. The layouts also vary accordingly. A reasonably equipped sheet metal fabrication shop should have at least the following:

Primary Section

- Sheet stalkers

- Power Shearing Machine, 2.5 Mt length, Hand Shears

- CNC Turret Punch Press, 24 stations, Power Presses- 20T,60 T, Fly Presses

Secondary Section

- CNC Press brake 2.5 Mt length, Hydraulic press brake. 2.5 Mt, Folding machine 1.2 Mt

- Notching Machine, Clinching machine, Riveting machine, Hand Riveting equipment

- Work Benches 2Mt length, Fitter Hand Tool Sets,

Integration Section

- CO2 Welding, TIG Welding, Arc Welding, Spot welding, Resistance welding

- Welding Tables, Welding Jigs

- Deburring, Grinding, Sanding

- Inspection Tables, Inspection Tools

Finishing Section

- 7 Tank Pre-treatment

- Conveyorized Spray painting, Powder Coating booths

- Effluent Treatment Systems

- Plating Systems

Assembly Section

- Assembly tables

- Assembly Documents

- Assembly jigs

- Pneumatic Screwdrivers

- Cleaning Systems

Dispatch Section

- Packing

- Dispatch Documents

- Jib Crane or other lifting equipment

TYPICAL LAYOUT OF A SHEET METAL FABRICATION SHOP. MACHINES CAN BE MORE THAN ONE.

Production should be planned based on firm BOM and BOQ along with formatted final drawings, not as-built drawings

Sheet Metal production initiation generally comprises of:

- Work Order Generation

- Production Flow path creation

- Man, and machine time planning

- Quality manual generation

- Inspection manual generation

- Dispatch document generation

The production begins with these documents. There must be periodic in-process quality checks and final quality checks before the product is certified for dispatch.