Design Resource

Bell Metal Design of Orissa

The Craft of Moulding Metals

by

The Procedure

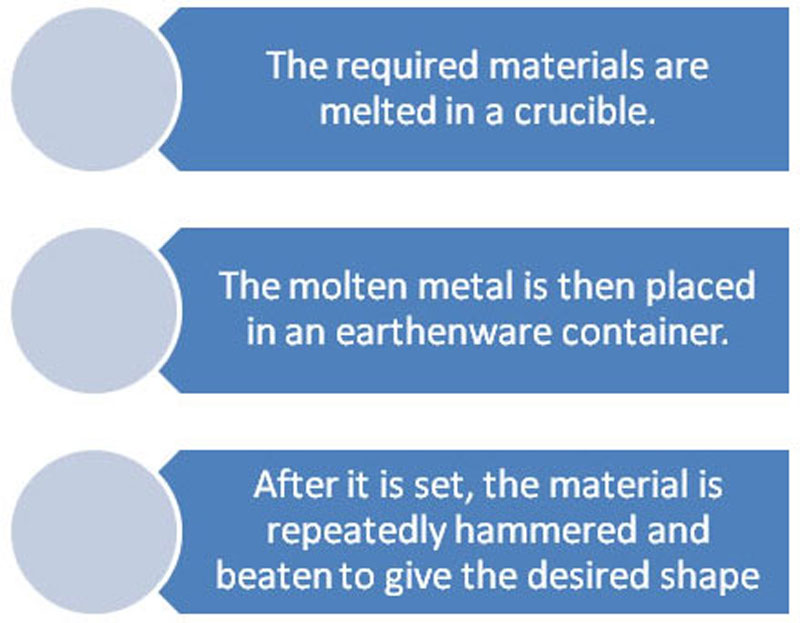

The procedure is as follows:

The major items manufactured in the beating process are plates or ‘Thali’, deep round containers called ‘Kansa’ , small containers called ‘gina’ (tumblers), water containers called ‘Ghara’, large cooking utensils called ‘Handi’ , various types of pots and pansand ladles or ‘Chatu’.While the above mentioned items are used in cooking there are some items used for ‘puja’ or ‘worship’, of these most important are the ‘Ghantas’ or ‘Gong’andthali for keeping offerings to the god. There are even geometric and floral patterns engraved on some and are paited with enamel paints. The designs vary from place to place.

Brass Metal Engraving:

Earlier when paper was not developed brass and other metals were used for writing and keeping accounts for kings. This text was maintained by the king as a permanent record. Later craftsmen used this craft to explore their skills even more. Brass has an importance in the Hindu mythology and Vedas. It continues to maintain its importance even today.

Process description:

1. The scrap metal is melted at high temperatures.

2. The molten metal is then put in a mould.

3. The metal is then heaved out of the mould.

4. It is light hammered at the edges to bend sharp corners.

5. The artisan then aligns the two parts of the pot together.

6. The artisan then checks for the accuracy of the aligned parts of the pot.

7. A local adhesive is applied at the joining of the parts and is heated at high temperatures.

8. The pot is lightly hammered to make it more durable and long lasting.

9. It is then polished with a local grease to improve the surface texture.

10. Small dents are then made on the pot to improve the aesthetics and the pot is now ready to be marketed.