Design Course

Sheet Metal

Fabrication Technology in Product Design

by

Assembly without Fasteners

Fasteners cost money. Fasteners contribute to the increase of Bill of Materials (BOM) besides inventory costs. It is possible in sheet metal product design to assemble parts without fasteners.

One wonderful property of sheet metal is its rigidity yet at the same time flexible enough for easy assembly. Here we observe a shelf that can be installed to a rear bracket without fasteners. Notice the upper lip in the rear bracket to facilitate hooking.

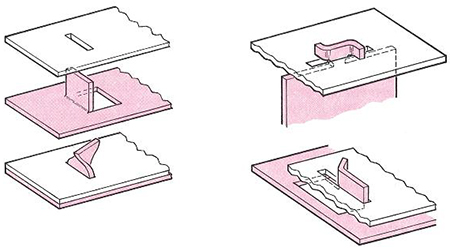

Assembly with Tongue and Groove

Tongue and Groove detail (Image Courtesy: piterest)

It is very convenient to adapt tongue and groove joints for detaching sheet metal parts from one another using tongue and groove systems. A tongue designed at the end of a component gets inserted into a groove of another component with a slight play. The width of the tongue should be sufficient enough to firmly sit in the groove but not allow too much play.

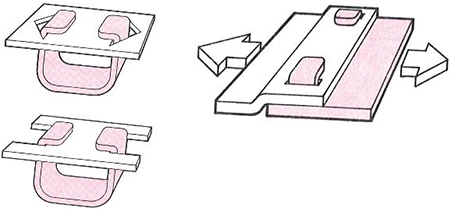

Use of Studs, Keyholes

Studs and keyholes can be provided in the panels at mating places to enable hooking one panel to the other. The studs may be a simple stud welded to the panel or a clinch stud that can be clinched to the sheet bending into a panel.

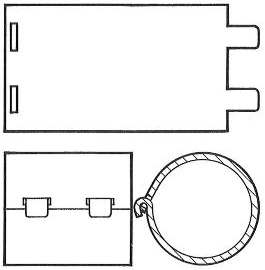

Standard Keyhole clinch Studs.

Standard Keyhole clinch Studs. Standard Keyhole clinch Studs.

Standard Keyhole clinch Studs.

keyhole in the chassis. Panels are hooked on to chassis for easy removal

keyhole in the chassis. Panels are hooked on to chassis for easy removal Typical engineering details of a keyhole joining fastener - Courtesy: Penn Engineering

Typical engineering details of a keyhole joining fastener - Courtesy: Penn EngineeringAssembly Using Hemming

Hemming is one of the best ways to join two sheet metal parts without fasteners. This process needs to be adapted in joining two sheet metal parts into a sub-assembly before assembling of internal components.

Minimum hemming area.

Minimum hemming area.Assembly Using Clinching

Clinching joint is a sheet metal operation to permanently join two sheets together This method can be used to join two flat areas of sheets using the cold heading method. It creates a button type between two or three types of sheets.

It is a cost-effective process of joining sheets of metal without the sparks, fumes, and potential material damage that can be caused by spot welding. Basically, this quick and easy metal fastening method does not create heat or require pre-drilled holes.

Assembly using Snap Fits

Spring force can be used to fasten parts together. The figures below illustrate the type of fastening effect that can be achieved with spring-type holding devices. The assembly operation requires only that the spring or spring-like receptacles be snapped into place.

Examples of snap fits (Courtesy : DFA by James.R.Bralla)

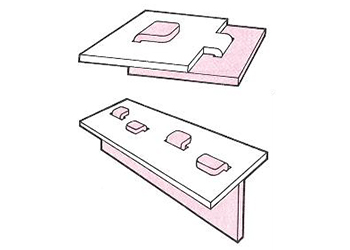

Assembly using Tabs

(Image Courtesy: Stephen Mraz)

Tabs or tongues are formed by punching operation in one of the parts. The mating part will have a corresponding slot that is slightly larger than the tab for easy insertion. The tab is then folded at 90 deg and pressed onto the mating part to form the joint. Tabs can vary in size and shape for appearance and make assembly easier.

Tabs can also be twisted instead of folding.

(Image source)

Slot Shapes

(Image source)

Slots need always be rectangular shapes. They can be triangular or even notches. Joint strength can be increased by folding the tabs in opposite directions.

Self-Locking Tabs

(Image source)

Assembly does not always involve two or more parts. The same part can be joined to itself, one end to another, by folding tabs. This image shows how a tube can be formed using tabs.

Redundant Tabs

Tabs are sometimes used as redundant details. They may be used if required by bending and aligning or tearing them if not required.

Assembly using Hinges

There are many types of hinges available to suit individual applications. Hinges have to be chosen keeping in mind primarily the weight of the part and frequency of use and ease of assembly. If a door has to be removed completely, say for servicing of a cabinet, spring-loaded pin hinges or pivot hinges are most appropriate. Large size products such as control panels, Consoles may need piano hinges to support heavy rotating doors.

Example of the extruded hinge as shown here with no need for a pin to create the hinge. In this example, the gear also offers good torque facilitating a tight turn for the flap.

(

( (

( (

( (

( (

( keyhole in the chassis.Panels are hooked on to chassis for easy removal.

keyhole in the chassis.Panels are hooked on to chassis for easy removal. Hemmed parts.

Hemmed parts. Clinching Joint.

Clinching Joint. (

( Clinched assembly.

Clinched assembly.

(

( Tongue and slot.

Tongue and slot. Floded tab.

Floded tab. Types of tabs.

Types of tabs.

(

(