Design Gallery

Karvat Kathi Saree Weaving on Handloom

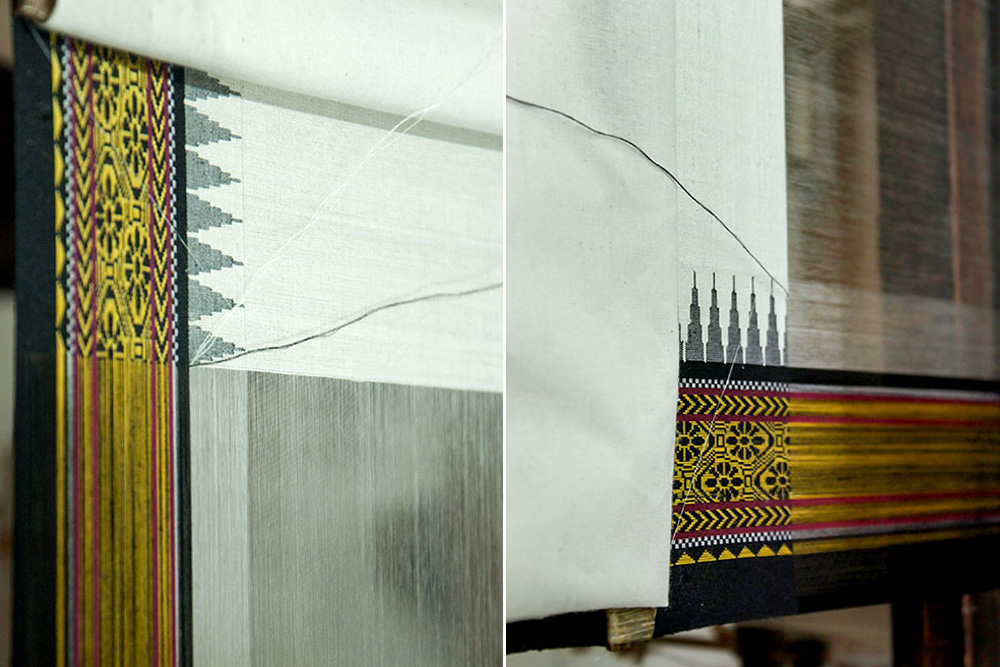

Saw-edged Saree

by

The Karvat Kathi sarees and fabrics curated in Maharashtra originated in the Vidarbha region of the state, which is now an indispensable part of their culture and livelihood.

The temple designs throughout the borders produced in various sizes are what make this style stand out from other weaving styles. Under the instructions of Mr. Y. K. Suryavanshi, Deputy Director at Nagpur-based Weavers Service Center, senior artisans like Mr. Pasan Shetty, Mr. Gajanan Dhekate, and many others employed at the center create this aesthetically upfront piece of art. They supply their produce to various state-owned handloom showrooms like Indrayani, a center run by the Government of Maharashtra.

Two types of looms are used for weaving Karvat Kathi saree namely Pitloom and Handloom. Nowadays, frame types of looms are mostly preferred over the traditional Pit loom to weave the Karvat Kathi saree. This new technology bestowed with metal frames is comparatively lightweight and craftsman friendly in the areas of working comfort and body movements. Both Pitloom and Handloom sarees were created at the Bunkar Seva Kendra’s ministry of textiles, bear temple borders, and fine detailing.

For more details:

https://dsource.in/resource/karvat-kathi-saree-weaving-nagpur-maharashtra