Design Gallery

Dhurrie Weaving - Nagpur, Maharashtra

Floor Coverings

by

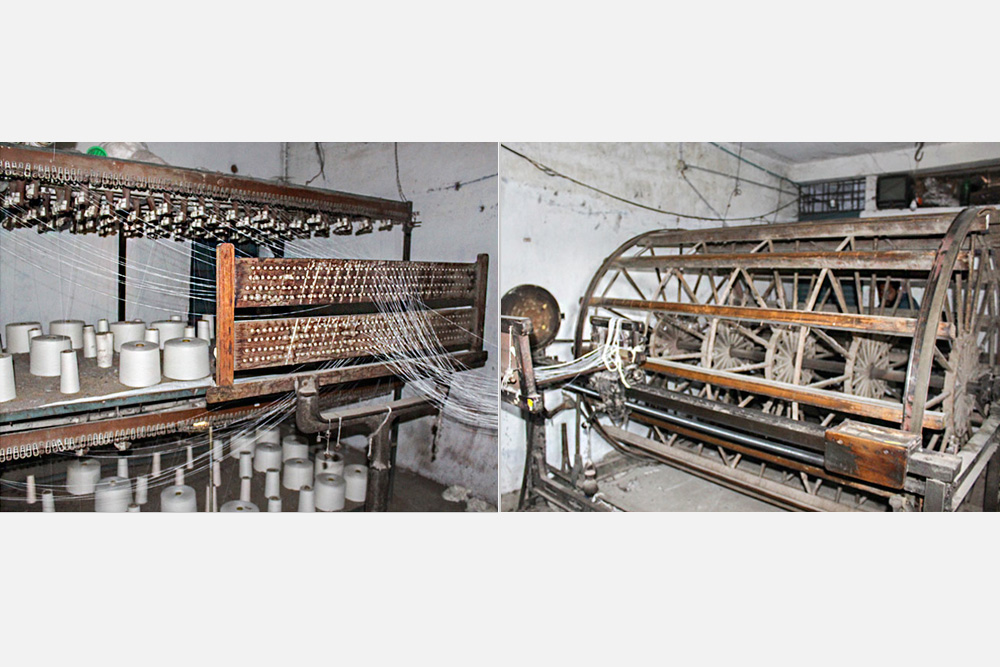

A Dhurrie is a thin woven rug similar to carpets, widely used as floor coverings. Their application can also be found in the bottom linings of bed covers and packaging items. This weaving technique is believed to have been brought to India by artisans from the Mughal Empire. A handloom machine is used for the Dhurrie weaving. Compared to other forms, this type holds bolder designs and is thicker in size. During the making, the weaver coils the threads of the weft on a shuttle and then slides this through the warp to make the indented fabric. Cotton and wool fiber is usually used for Handloom Dhurrie, though jute fibers are also incorporated at times.

Each region houses its distinctive Dhurrie creations with varied patterns and colour combinations. For example, Dhurries of Darjeeling largely hold Tibetan designs featuring dragons and cloud motifs. Dhurries are fashioned in vibrant hues in the south, while the most elegant variety is from Navalgund, a small town of Karnataka. It is also manufactured in Nagpur, Maharashtra. Mr. Abdul Ansari is having a manufacturing unit of Dhurrie weaving in Nagpur. These Dhurries are mostly woven in cotton fibers, which makes the product more absorbent, soft and enables easy dyeing.

For more details:

https://dsource.in/resource/dhurrie-weaving-nagpur-maharashtra