Design Gallery

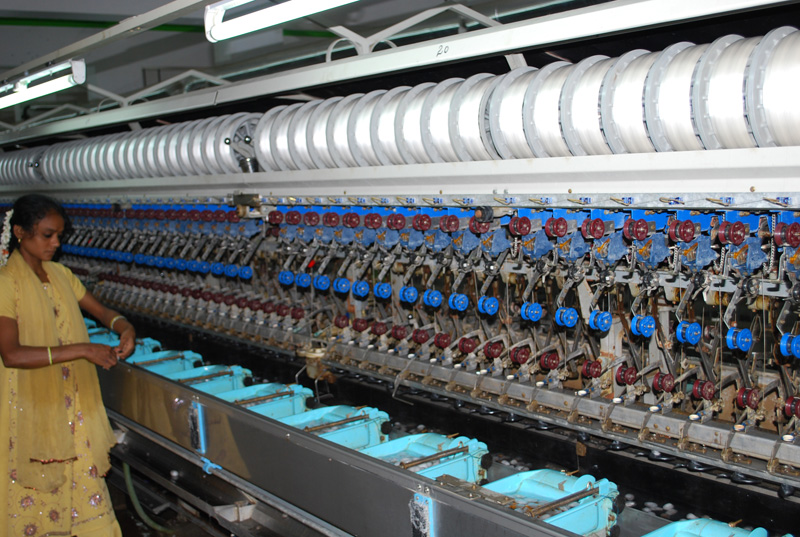

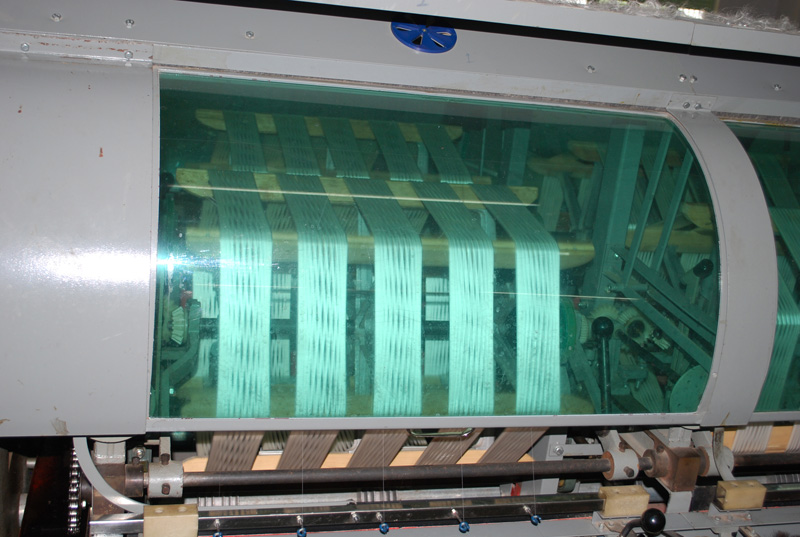

Silk Reeling

by

Located about 48 km southwest of Bengaluru, Ramanagara became a separate district in 2007 and is renowned for its silk production. It houses Asia’s largest cocoon market and is a major center for sericulture in India. Known for producing some of the finest Mulberry silk, Ramanagara is home to various silkworm breeds, especially the class B Mori variety, commonly found across the country. The district plays a vital role in India’s silk industry and remains a key hub for both silk trading and sericulture development.

For more details:

https://dsource.in/resource/silk-reeling