Design Gallery

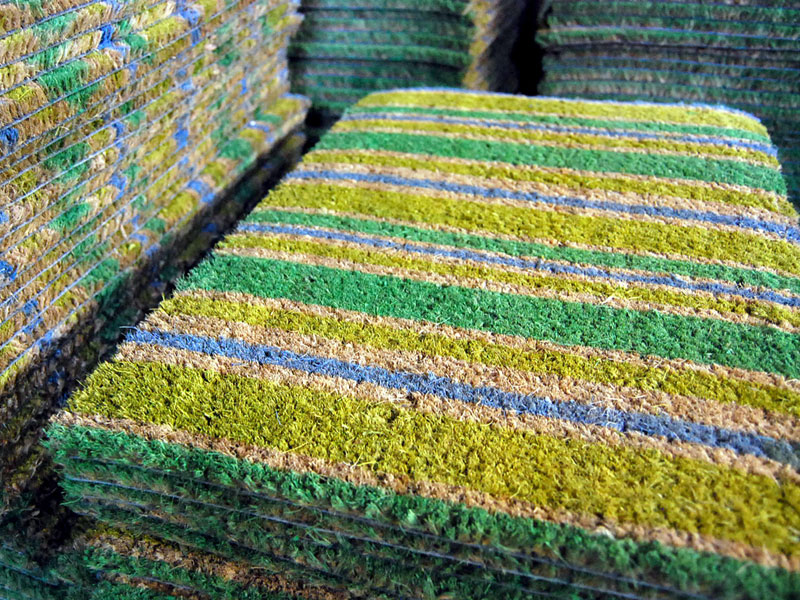

Coir Craft - Kerala

by

The coir making process is a traditional craft of the people of Kerala as coir is available in abundance in the state. The artisans follow the traditional as well as the mechanical process of extracting fibre, twisting, spinning and making of twines and other products from coir. Kerala produces a great variety of products made out of coir as a raw material. The commercial production of coir in Kerala dates back to the ninetieth century and has become the largest cottage industry in the state, employing millions. The coir fibre is elastic and flexible to twist without breaking and it holds a curl as though permanently waved. The coir fibre is water-proof and resists damage against salt water. The sea water and fresh water is used in the production of white coir.

For more details:

http://www.dsource.in/resource/coir-craft-kerala