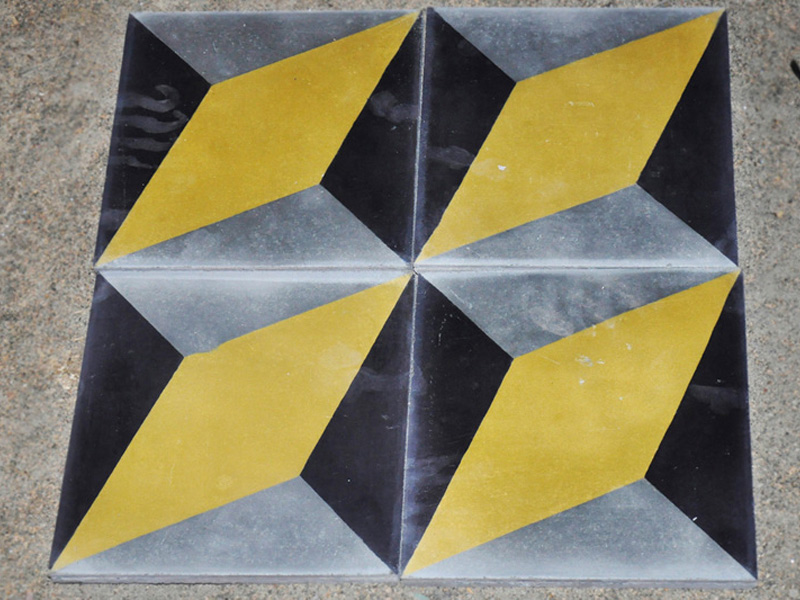

Design Gallery

Athangudi Tiles Making - Karaikudi

Making of Decorative Floor Tiles

by

Cement and sand and baby jelly is mixed with water and converted into dough. To make the colors, artisan mixes color with sand, cement and water turning it into a thin paste. The machine mixes the materials and converts them into much finer paste. The metal border frame is placed on the glass slab which is used as the base for the tile. Design frame is placed on the glass slab to make the design. Color solution is poured in different compartment of the frame as per design. Dry mixture of sand and cement is sprinkled on the colored layer to avoid mixing of colors.

The pre-prepared dough is spread on the design and then leveled. The border frame is removed and the tile is kept to dry in room temperature for overnight. Then the dried tiles are soaked in water tank for 6 days. Later they are kept in sunlight to dry. When dried the glass frame automatically ease out. The glass slab leaves a shine and luster effect on the final product.

For more details: http://dsource.in/resource/athangudi-tiles-karaikudi